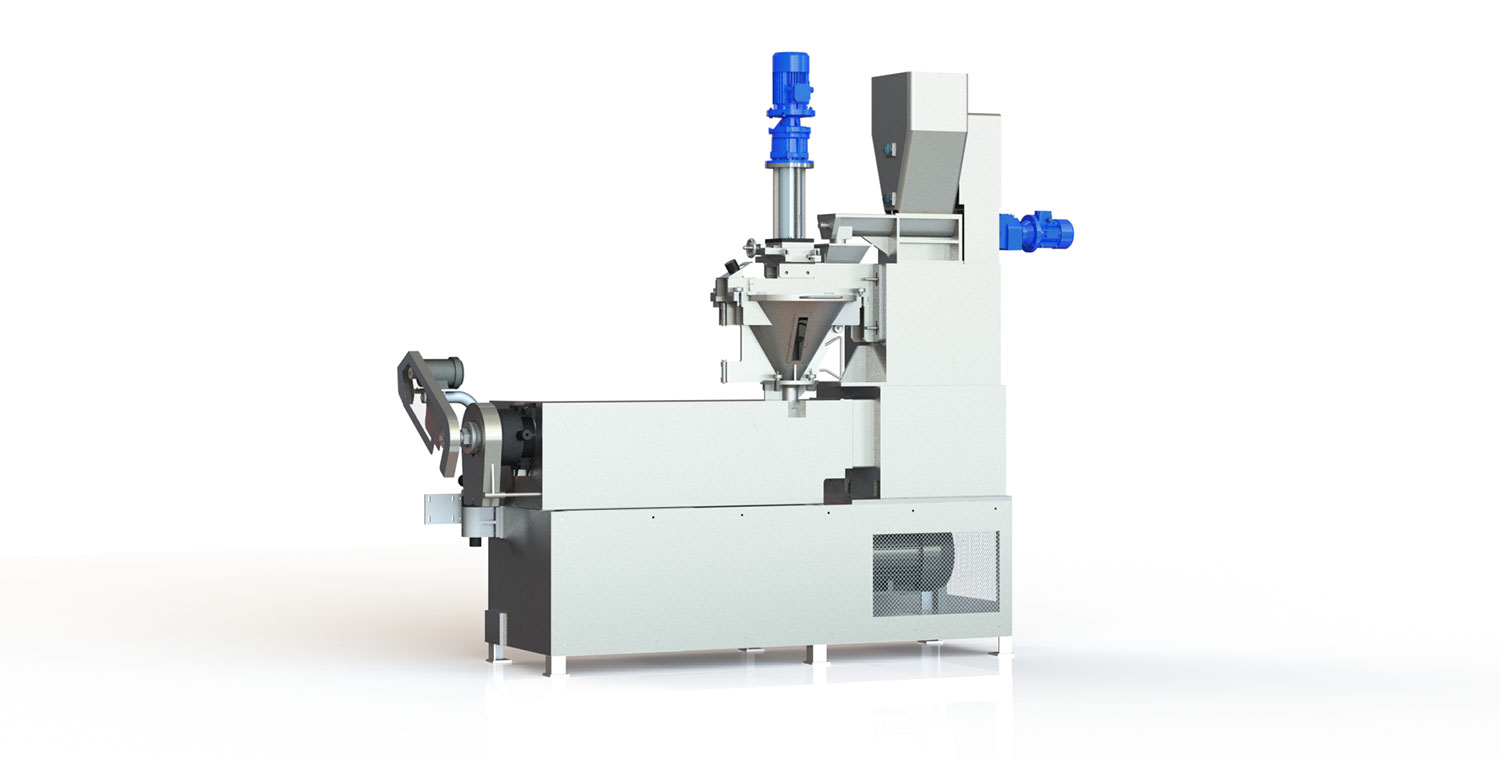

(MC-1102RX) COOKING-FORMING EXTRUDER

Extruded 2D/3D Pellet Line

The mixed raw materials are dumped into the hopper and fed to the extruder barrel via a screw feeder. Feeding amount is controlled by a level sensor. Screw is 75 mm dia. and diameter-length ratio is 1:20. The raw materials that are fed to the barrel are cooked by the heat induced by mechanical friction and pressure. Final shape is determined by the Die-Insert Nozzles (one set included).

NP & Company is the industry-leading manufacturer of steam-cooked Snack Pellet Line, Extruded Snack Pellet Line, Coated Nuts Line, Pop Chips Line, Chocolate Vacuum Absorption Line, and many other machineries. NP is a total snack manufacturing solution provider. From NP’s supremely innovative, high-quality snack making solutions and systems that can address virtually any snack or pellet application in any market. From producing a pellet to fryer, roaster, seasoning, and even packaging, NP has a solution for you.

SPECIFICATIONS

Capacity

Nominal output is 60 to 120 kgs per hour.

Output may vary considerably depending on raw materials used, formulation, product shape, product size, etc.

Power Requirement

50.65 kW

Dimension

3,395 mm (L) x 850 mm (W) x 2,320 mm (H)

Main Drive

30 kW variable-speed motor x 1, 0.4 kw x 1 and 0.75 kw x 1

Body

Heavy-gauge, sanitary stainless SUS202

Vertical Force Feeder

For uniform feeding on the barrel

Barrel

3 segmental barrel; separately controlled temperature for versatility

Screw

75mm diameter high compression screw

Die Head

Downward type for uniform extrusion; controlled heating installed

Nozzles

Insert type for easy and inexpensive repair and replacement; design as per customer

HMI

Touch screen remote panel for convenience of control

Hydraulic Jack

For easy removal of screw

*Requires Temperature Control Unit for water recirculation (whichever applicable in customer’s side)