EXTRUDED PELLETS MANUFACTURING LINE

Extruded 2D/3D Pellet Line

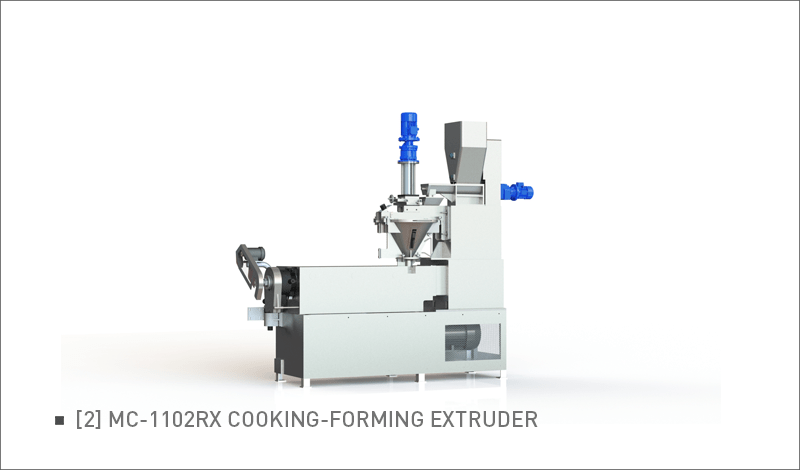

The main machine, MC-1102 Cooking/Forming Extruder is so called “Single Screw Extruder”. Raw material is kneaded under high pressure and cooked by the frictional heat produced between the barrel and screw. The forming nozzles (dies) at the outlet form the shape of the dough such as ring shape, star shape, etc. The dough is then cut to make pellets (half product for snacks) which would be dried to appropriate moisture content for either frying or roasting afterward. Variety of shapes (length, thickness, etc) are obtainable depending on the cutting method, either by cutting blade installed on the extruder right after the outlet of the dough or optional cutting systems available such as intermittent cutting to get long products (tube over 30mm) or high speed rotary slicer to obtain extreme thin pellet, etc.

For further information, please refer by clicking each machine’s picture.