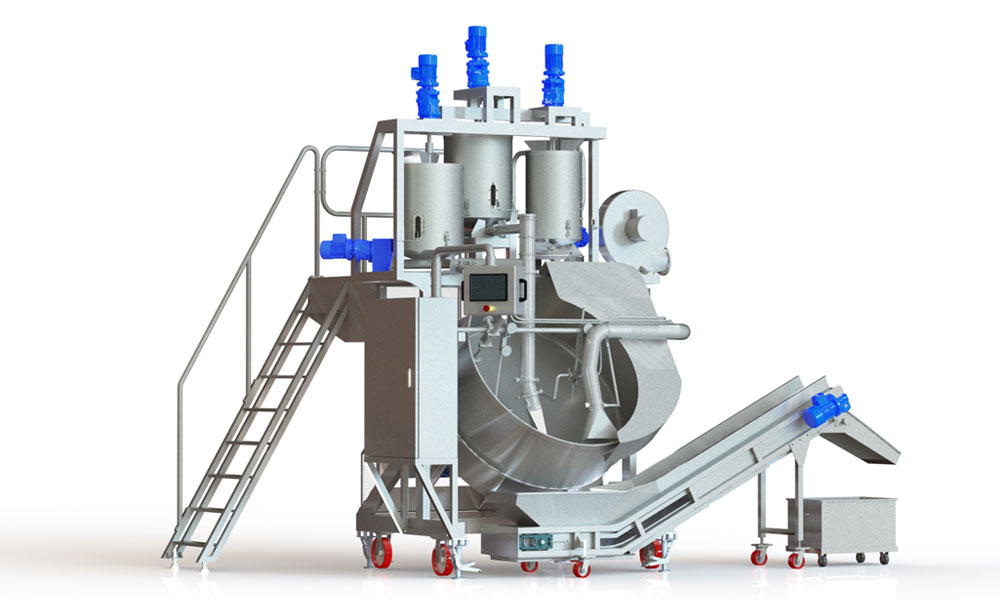

(APR-100R) AUTO/MANUAL POWDER COATER

Coated Nuts Line

The APC-100R with Automatic Discharge Conveyor and Powder Sifter.

The Powder Coater consists of a coating tumbler, a powder dust collector with powder feeder and liquid feeder, auto discharge to the conveyor with powder sifter. Raw materials such as raw peanuts or fried peas are fed into the tumbler manually. The tumbler continuously turns so that the raw materials can be coated by intermittently automatic/manual application of syrup and powder until it forms to the desired size of coated nuts.

NP & Company is the industry-leading manufacturer of steam-cooked Snack Pellet Line, Extruded Snack Pellet Line, Coated Nuts Line, Pop Chips Line, Chocolate Vacuum Absorption Line, and many other machineries. NP is a total snack manufacturing solution provider. From NP’s supremely innovative, high-quality snack making solutions and systems that can address virtually any snack or pellet application in any market. From producing a pellet to fryer, roaster, seasoning, and even packaging, NP has a solution for you.

SPECIFICATIONS

Capacity

Approx. 80-120 kgs/hr of coated cashew

Dimension

1,840 mm (L) x 2,300 mm (W) x 3,420 mm (H)

Coating Tumbler

- 1350 mm (Dia.) x 470 mm depth

- Stainless steel SUS304

- Auto-discharge gate by pneumatic cylinder actuator

- 1.5 kW drive motor, variable speed

Powder Applicator

- 80 L capacity, stainless steel tanks

- Collapsible design for cleaning

- Twin screw feeder, HDPE

- Mixing paddle, stainless steel

- 0.55 kW screw feeder drive, variable speed

- 0.18 kW mixing paddle drive

Liquid Mixture Applicator

- Main tank, 40 L capacity, stainless steel

- Secondary tank, 8 L capacity, stainless steel

- 3-way valve with solenoid for auto-liquid selection

- 0.37 kW tube-pump drive, variable speed

Others

- Mild steel structural body frame, acrylic paint finish

- PLC electric control panel with touch screen HMI